Welcome to book it in advance

1.you can get the biggest discount

2. your parcel will be sent first.

if you have driven a car with an inline-six engine, you will find the L6 engine appealing because its perfect balance helps for smooth, easy revs, and the soothing exhaust note, just like the burbling of a freshwater stream. More importantly, its simple layout guarantees less maintenance.

Is V6 or inline 6 better? The in-line 6-cylinder is a very old form of cylinder arrangement. It was mass-produced for the first time in 1903. Many car companies have built in-line 6-cylinder engines, and many classic models have been born. However, due to the inherent imbalance of the V6 engine, it is necessary to be Half a century later than the L6 engine. The biggest difference between the two is the arrangement of the cylinders. The in-line layout means that all the cylinders are arranged in a straight line, and the V-shaped layout means that the cylinders are divided into two groups and arranged in a V shape at a certain angle.

From the perspective of the cross-section, 1-6, 2-5, and 3-4 are the corresponding cylinders, that is to say, when the piston of cylinder 1 moves downward, the piston of cylinder 6 moves upward, and the same is true for cylinder 2-5 and cylinder 3-4 In this case, the symmetrical distribution of the pistons by the center of gravity of the cylinder cross-section can cancel the natural vibration frequency of the pistons when they move. When the engine is running, the entire L6 engine is symmetrical along the center line (axis of symmetry), while the position of the crankpin of the V6 engine is more like two in-line three-cylinder engines arranged side by side, which means that the cylinder on one side There will be two pistons that move up and down at the same time, and the other piston moves in the opposite direction, so it can't be self-balancing. The inline six is more reliable than the V6 engine because it only needs one set of cylinder heads, or in other words, whether it is the intake air The manifold, fuel injection system, ignition or exhaust manifold do not need to be designed in two parts, which simplifies the mechanical structure. For machinery, there are more parts, and the failure rate may be higher. Neither car companies nor consumers can accept an engine with a high failure rate. Therefore, the inline six-cylinder engine has an advantage in use stability.

The inline 6-cylinder engine can achieve a balanced state inherently, so there is no need to install a balance shaft like a V6 engine. In addition, the 6 cylinders of the L6 are integrated, requiring only one cylinder head, one set of the gas distribution system, and two camshafts. The V6 engine requires two independent cylinder liners, two sets of gas distribution systems, and four camshafts due to the left and right sets. So from a cost point of view, L6 is more economical. For a long time, the V6 engine was the mainstream form of the 6-cylinder engine, but now there are more and more L6 engines. But now many car brands are starting to recreate the L6 engine. The biggest reason is that modular design can reduce costs.

The V-shaped engine can shorten the length and height of the engine, making the engine compartment lower. The final glory of the V6 engine was between 2001 and 2010. During this decade, many car brands have launched high-performance civilian six-cylinder engines (while ensuring performance, fuel consumption, and reliability). Therefore, the reason why V6 and L6 were so popular in that era, showing a state of flourishing, was mainly because of the concept of internal combustion engines and the relaxation of rules at that time. Restricted by environmental protection rules, engineers of various companies do not have to worry too much about fuel economy when creating performance, because performance and fuel consumption are contradictory words.

The inline six-cylinder is gradually replaced by the V6 in family cars, but it is still the first choice in some luxury cars, because there is enough space to place the engine, and its smooth driving experience cannot be provided by the V-type cylinder. Maybe one day in the future, the fuel engine will be completely replaced by the electric motor, and the perfect and scarce inline six-cylinder engine will always exist only in memory. Would you consider putting a inline six engine in your collection cabinet?

How about a six-cylinder engine?

Many car enthusiasts may ask this question. In this era of 4-cylinder engines, 3-cylinder engines as substitutes, and electric vehicles around the corner, talking about whether the 6-cylinder engine is good or not feels like an overhead timeline. If the 6-cylinder engine is good, so it's embarrassing to find not many left so far; and if it's not good, many legendary 6-cylinder engines have been born in the history of internal combustion engines. Even though some models are extremely rare today, they still have a high reputation among the majority of car fans and enjoy a high reputation. You can use dialectical thinking to see whether these extremely classic 6-cylinder engines are good or bad. Perhaps in the era that belonged to them, they all exuded dazzling light. But nowadays, it may be just feelings, feelings are "priceless", and hard to buy. The "goodness" of an engine should not only be reflected in its performance because there are too many variables in the soil suitable for its existence. This is like asking whether the steam engine is good in the era of the internal combustion engine. Whether it is good or not, there is no way to replace the steam engine.

We like 6 cylinders, 8 cylinders, and 12 cylinders not because of how smooth they are, but because we know that the engine with more cylinders is better, not because of it is smooth or not. Therefore, human emotions often give different definitions to the same thing. We like the 6-cylinder engine more because of our yearning for beautiful things. It is actually difficult to find out how good it is after really using the 6-cylinder engine. Well, it is more reflected in psychology, and it can be understood as a kind of spiritual victory. So how good the 6-cylinder engine is is more because it used to exist and was excellent, but now it has gradually withered. We are more nostalgic for the good things that used to be because what we can’t get is always the best.

Under such background, the Howin team began to think about making an inline six-cylinder engine, because its smoothness cannot be replaced by a V-type engine. In the end, Howin chose to use the Ford 300 straight-six replica as the prototype, because it has smooth power, strong expandability, and can be jointly developed with other engines, which makes the F300 straight-six engine their final choice. At present, there are very few model engine manufacturers to produce inline six-cylinder engine models, because this requires a certain amount of research and development and trial and error costs. For example, the crankshaft is easy to break due to the concentricity during processing, which requires a high processing technology. Howin used a unique processing method to avoid this problem and optimized it.

In an inline six cylinder engine, each cylinder doing the combustion stroke is balanced by another cylinder doing the intake stroke, and these "pairs" of cylinders are usually located symmetrically around the center point of the crankshaft, so there is very little vibration as a result It's an inline six cylinder engine. This is because each cylinder in an inline six cylinder engine has a mated cylinder that is doing its intake stroke, which creates a symmetrical vibration, where the magnitude of the symmetrical vibration is smallest near the center point of the crankshaft, So it has much less vibration than other engines.

If the HOWIN L6 engine model cannot be started successully, please contact us with photos to video its status for a new distributor. The new one is mainly adjusted the internal structure and wiring method of the distributor.

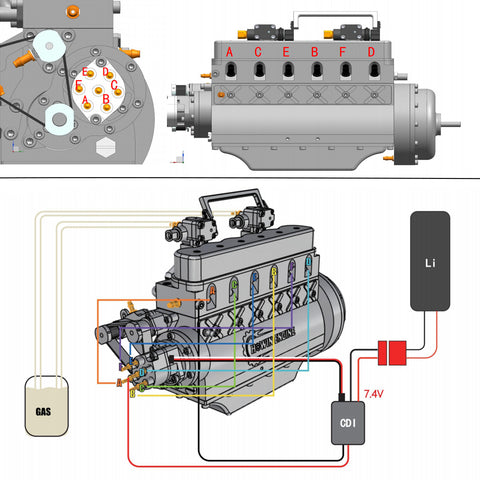

Here is the wiring diagram for the new distributor. (June in 2023 )

In general, inline-six engines tend to produce a more pleasing exhaust note than V6 engines. , the exhaust sound of the inline six-cylinder engine is more classically magnetic and soft than the V6 engine, more like a cello string, while the V6 engine is more like a violin string, more rhythmic and more passion.

Two Facts Howin Has Found during the Manufacturing Process of Howin engine.

1. It's more difficult to machine a 6 cylinder engine than four-cylinder

Because the camshaft and crankshaft are long, it is difficult to guarantee the concentricity. Processing is a difficult problem. It is difficult to balance the concentricity and toughness in processing. So the crankshaft and camshaft are a bright spot.

2. The inline 6 engine has a bigger size than that of four-cylinder

It can be used with 1/8 1/7 1/6 model cars. The six-cylinder engine is stronger in power and displacement than the four-cylinder engine. The inline six-cylinder structure is also a very stable structure. It can provide the most powerful while smooth transmission and horsepower.

Howin will also give you 3 surprises for you when you get your parcel in the future. All will receive the upgraded inline six engine, which is a little bit different from our sample. So where does Howin change?

A. The distributor. The old version of the distributor uses screws with low hardness. The bulk version has been improved to high hardness screws.

B. The two holes in the middle. The original intention is to use the ejector rod to withstand the camshaft and prevent it from deforming. Now the new version has solved this problem, so there is no need for the ejector rod to withstand the camshaft.

C.The shape of the exhaust pipe and the carburetor pipe. The old ones are straight, which will lead to uneven exhaust, so the new ones will avoid this situation happening.

Learn more from the photos below.

Frequent Questions People Might Ask

1. Hey will you guys make a inline 3 and a inline 5 and also inline 6?

Hello, Howin choose the make the inline 6 this time. maybe in the future they will consider making a inline 3 or a inline 5.

2. What are all the fluids underneath the engine? Is it nitro fuel oil waste?

The prototype is what we are testing, and the liquid is water. The water pump and oil pump are not added, the shipped version will add a water pump and a drain.

3. How Much Does it cost for a Inline Six Engine Model?

Q: What is the displacement of the HOWIN Inline 6 Cylinder Four-stroke Gasoline RC Engine?

A: The displacement of this engine is 22-25cc.

Q: What is the valve mechanism of this engine?

A: The valve mechanism of this engine is OHV ejector rod gas distribution structure.

Q: How does this engine cool itself?

A: This engine uses water cooling for cooling.

Q: What is the lubrication method used in this engine?

A: This engine uses independent lubrication with an oil pump.

Q: What type of ignition system does this engine have?

A: This engine has a distributor ignition system.

Q: How is this engine manufactured?

A: This engine is manufactured using CNC machining.

Q: Is this engine available in kit or finished version?

A: The availability of this engine in kit or finished version is currently unsettled.

Q: What scale of RC car is this engine suitable for?

A: This engine is suitable for 1/8 or 1/10 scale RC cars.

Q: What are the applications of this howin engine?

A: This engine can be used in modified RC cars or as a desktop engine.

Q: Can this howin engine be used in both gas and electric RC cars?

A: No, this engine is specifically designed for use in gasoline-powered RC cars.

Q: Is this engine easy to assemble and install?

A: Assembling and installing this engine may require some technical knowledge and experience, so it may not be easy for beginners.

Q: What type of fuel is required for this engine?

A: This engine requires gasoline as its fuel.

Q: Can this engine be used for other applications besides RC cars?

A: While it is specifically designed for use in RC cars, it may be possible to adapt it for use in other applications with appropriate modifications.

Q: What is the price range for this engine?

A: The price range for this engine is not specified by the manufacturer, and may vary depending on the version and where it is purchased.

Q: How do I maintain my inline six engine?

A: Regular maintenance, such as oil changes, air filter replacement, and spark plug replacement, can help ensure the longevity and performance of your inline six engine. It's also important to follow the manufacturer's recommended maintenance schedule and address any issues as soon as they arise.

Q: Can anybody rotate their Howin L6 Engine by hand? I cant. And wonder if its even gonna run at this point.?

A: The crankshaft of the straight six is very long, and the internal pressure and the friction brought by the piston connecting rod will make him choose a certain resistance. At this time, if you want to turn the crankshaft by hand, you need to bring a flywheel to rotate it. Turn the crankshaft to increase the torque. You can also add a little lubricating oil to the connection between the piston and the connecting rod to make it more perfect. Holding the crankshaft by hand alone is too little torque and too much friction

related blogs

HOWIN Designs & Makes Inline 6 Cylinder Engine L6 Now

I am very impressed. Please put my name on the excited buyer list.

An engineering marvel!Please put my name on the waiting list.👍👍

Yep! Ya can tack my name on the waiting list & Hope the production isn’t held up like my V8 enjomor G52 as my collection is slowly growing in to a comprehensive & interesting display of minature internal combustion engines….

Great engine! Put me on the list to get one as soon as it is available..

Beautiful. Please put me on the list